Ladder Type

Ladder Type Cable Trays

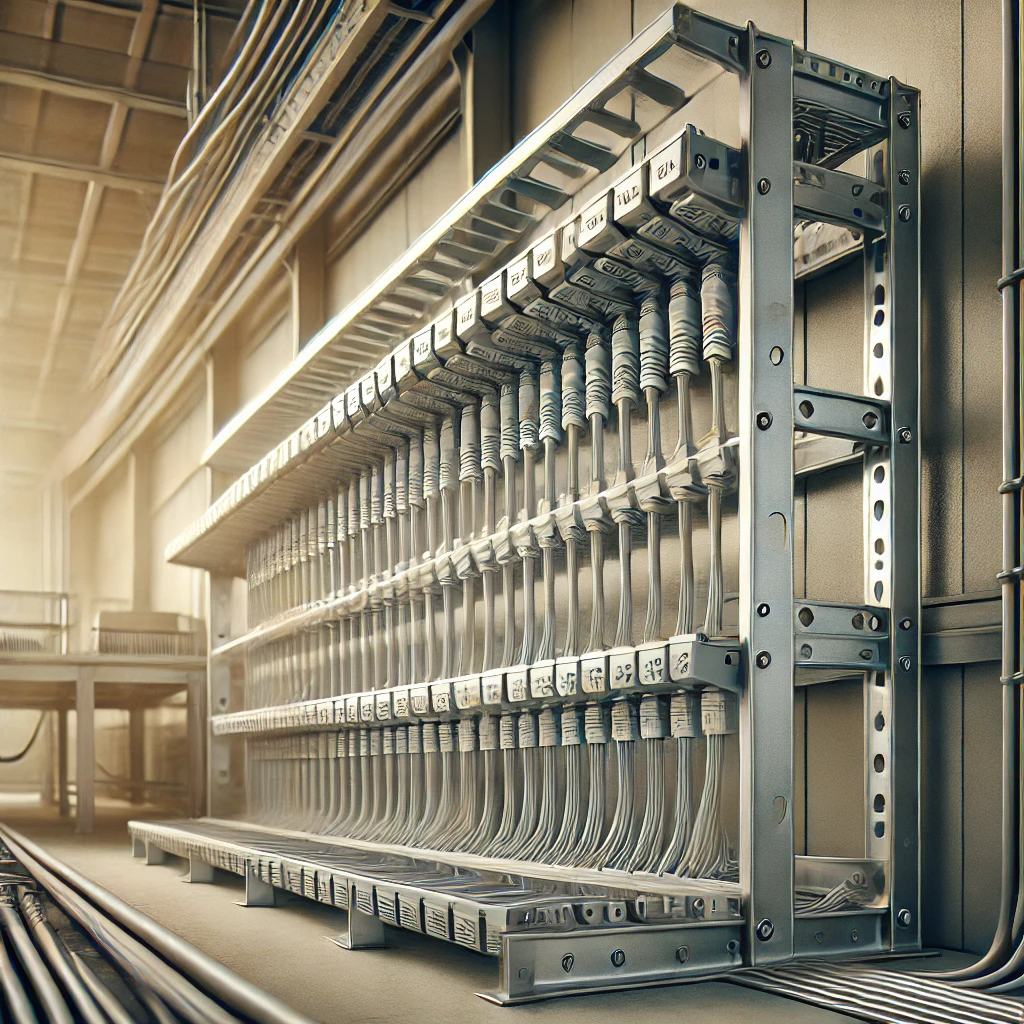

Ladder type cable trays are one of the most widely used cable management systems in industrial, commercial, and infrastructure projects. These trays consist of two parallel side rails connected by rungs at regular intervals, resembling a ladder. They provide excellent cable support, ventilation, and ease of maintenance, making them ideal for carrying power and communication cables.

Features of Ladder Type Cable Trays

Open Structure Design

- Allows for easy cable installation, inspection, and maintenance

- Provides natural ventilation, preventing cable overheating

Strong & Durable Construction

- Typically made from mild steel, stainless steel, aluminum, or fiberglass-reinforced plastic (FRP)

- Can support heavy loads of power cables over long spans

Varied Widths & Heights

- Available in different sizes to accommodate various cable capacities

- Customizable based on project requirements

Corrosion & Fire Resistance

- Can be coated with galvanized, epoxy, or powder coatings for enhanced durability

- Suitable for harsh environments such as chemical plants and offshore installations

Versatile Installation Options

- Can be mounted on walls, ceilings, or supported by floor stands

- Accessories such as bends, tees, and reducers allow flexible routing

Types of Ladder Type Cable Trays

Ladder cable trays are available in different materials and finishes, including:

Galvanized Steel Ladder Cable Trays

- Ideal for indoor and outdoor installations

Stainless Steel Ladder Cable Trays

- Preferred in food processing, pharmaceuticals, and marine industries

Aluminum Ladder Cable Trays

- Lightweight yet strong, with excellent corrosion resistance

- Used in power plants, commercial buildings, and transportation hubs

FRP (Fiberglass Reinforced Plastic) Ladder Cable Trays

- Non-conductive, non-corrosive, and fire-retardant

- Best suited for chemical plants, wastewater treatment, and offshore applications

Advantages of Ladder Type Cable Trays

✔ Efficient Heat Dissipation: The open design prevents cable overheating and extends cable life.

✔ Ease of Maintenance & Inspection: Open access simplifies cable additions, modifications, and troubleshooting.

✔ High Load-Bearing Capacity: Suitable for heavy power cables with long-span support.

✔ Cost-Effective: Requires less material than enclosed conduit systems, reducing installation and maintenance costs.

✔ Flexible & Expandable: Easily adaptable to future cable routing needs.

Installation & Safety Considerations

- Proper Spacing: Ensure rungs are evenly spaced to support cables effectively.

- Load Capacity: Select a tray with adequate load-bearing capacity for the number and type of cables.

- Corrosion Protection: Choose the appropriate material and coating for the installation environment.

- Seismic & Environmental Factors: Consider earthquake-resistant supports and weatherproof coatings for outdoor use.

- Cable Fastening: Secure cables using clamps or ties to prevent movement and damage.

Conclusion

Ladder type cable trays are a reliable, cost-effective, and durable cable management solution used in various industries. Their robust design, flexibility, and ease of installation make them an ideal choice for carrying electrical, control, and communication cables in industrial and commercial settings.

MS (Mild Steel)

Mild Steel (MS) is a widely used material in construction, engineering, and industrial applications due to its strength, durability, and cost-effectiveness. It contains a low percentage of carbon, making it easy to weld and fabricate. MS products, including sheets, plates, pipes, and structural components, are commonly used in manufacturing, infrastructure, and general fabrication.

Features:

✔ High tensile strength and durability

✔ Easy to weld, cut, and shape

✔ Cost-effective compared to other metals

✔ Available in various thicknesses and sizes

✔ Can be coated or galvanized for enhanced corrosion resistance

Applications:

-

Structural frameworks in buildings and bridges

-

Automotive and machinery components

-

Piping and tubing for industrial use

-

General fabrication and manufacturing

Hot Dip Galvanized (HDG) Steel

Hot Dip Galvanized (HDG) steel is coated with a layer of zinc through an immersion process, providing superior corrosion resistance. This makes it ideal for outdoor and industrial applications where exposure to moisture and harsh weather is a concern.

Features:

✔ Excellent corrosion and rust resistance

✔ Long-lasting and low maintenance

✔ Strong adhesion of zinc coating to prevent peeling or chipping

✔ Withstands harsh environments and extreme temperatures

Applications:

-

Electrical cable trays and support structures

-

Outdoor steel structures, fences, and poles

-

Marine and coastal applications

-

Industrial piping and ductwork

GI Sheet (Galvanized Iron Sheet)

Galvanized Iron (GI) Sheets are coated with zinc to prevent rust and corrosion, making them ideal for roofing, fencing, and structural applications. Available in plain, corrugated, or perforated forms, GI sheets are known for their durability and versatility.

Features:

✔ High corrosion resistance due to zinc coating

✔ Lightweight yet strong for various applications

✔ Available in different thicknesses and finishes

✔ Fire-resistant and weatherproof

Applications:

-

Roofing and cladding in residential and industrial buildings

-

Ductwork for HVAC systems

-

Fabrication of storage tanks and containers

-

Electrical panel enclosures and protective covers

Powder Coating

Powder coating is a dry finishing process that applies a protective and decorative layer to metal surfaces. This process enhances durability, resistance to corrosion, and aesthetic appeal. Powder-coated surfaces are widely used in industrial and architectural applications.

Features:

✔ Scratch-resistant and durable finish

✔ Environmentally friendly – no harmful solvents

✔ UV and weather-resistant properties

✔ Available in a variety of colors and textures

Applications:

-

Architectural metalwork (gates, railings, and fences)

-

Automotive and industrial machinery parts

-

Home appliances and furniture

-

Electrical enclosures and metal panels

Aluminium

Aluminium is a lightweight, corrosion-resistant metal widely used in construction, transportation, and industrial applications. It is available in sheets, extrusions, bars, and custom profiles for various industries.

Features:

✔ Lightweight with high strength-to-weight ratio

✔ Naturally corrosion-resistant without coating

✔ Excellent thermal and electrical conductivity

✔ Recyclable and eco-friendly

Applications:

-

Structural components in construction and aerospace

-

Electrical conductors and panels

-

Automotive and marine applications

-

Decorative and architectural finishes

Stainless Steel (SS)

Stainless Steel (SS) is a high-quality metal known for its resistance to rust, corrosion, and extreme temperatures. It is widely used in industrial, commercial, and household applications.

Features:

✔ Excellent resistance to rust and corrosion

✔ High strength and durability

✔ Hygienic and easy to clean (ideal for food and medical industries)

✔ Available in various grades (304, 316, etc.) for different environments

Applications:

-

Food processing and pharmaceutical industries

-

Architectural and structural applications

-

Automotive and transportation components

-

Marine and chemical processing equipment

FRP (Fiberglass Reinforced Plastic)

Fiberglass Reinforced Plastic (FRP) is a strong, lightweight, and non-conductive material used in corrosive environments. It is commonly used for cable trays, grating, and structural components where metal alternatives are unsuitable.

Features:

✔ Non-corrosive and resistant to harsh chemicals

✔ Non-conductive – ideal for electrical applications

✔ Lightweight yet highly durable

✔ Fire-retardant and weather-resistant

Applications:

-

Chemical plants and wastewater treatment facilities

-

Electrical cable trays and enclosures

-

Offshore and marine structures

-

Industrial flooring and walkways